Thermal Camera Buyers Guide: Factors Worth Understanding

Thermal Camera Buyers Guide: 10 Things Worth Knowing

There are many different variations of IR Thermal Cameras on the market ranging from simple point-and-shoot or high-end industrial thermal imagers. Regardless of your intended application its worth knowing and understanding 10 important camera factors when comparing and looking at different Thermal Cameras. The Thermal Camera Buyers Guide will help ensure you buy the correct camera for your intended application.

8 - Emissivity & Reflected Temperatures

1 - Resolution

Resolution is arguably the most important factor when choosing your thermal camera. As expected, higher resolution thermal cameras offer greater detailed visual data.

Detector resolution: Indicates the number of detector pixels on the camera. Higher pixel count, means a higher resolution.

Spatial resolution: Is based on detector pixels and the field of view (FOV) specification. Combining both factors defines the area the thermal camera imager visualises at any given moment under testing. Spatial resolution can be used to define the smallest object size that can be detected. A lower spatial resolution value results in better detail and image quality.

Professionals require high quality data to ensure data interpretation and analysis is accurate and reliable. Thermal cameras offering high pixel counts and resolutions command a higher price than those instruments with a lower pixel count.

2 - Focus

Focus mechanisms vary depending on brand and model. It is important to take into account your intended application and user skill level when assessing which thermal camera is best suited.

- Fixed: Point and shoot simplicity - reliable, fast and minimal user experience required;

- Manual: Precise incremental focus - highly-skilled user with experience necessary;

- Auto Focus: Automatically focuses on a target but may require manual adjustments;

- Laser-assisted Auto Focus: Features a built-in laser distance meter to calculate distance to the target;

- Multi-focal: Captures and stores multiple images of the target from varying focal distance and uses software to blend them into one image with ultra-sharp depth of field detail.

Fixed - Fluke PTi120 Compact Camera Laser Assisted Focus - Fluke Ti300+

3 - Temperature Range

The highest and lowest temperature you expect to encounter in your inspections determines the temperature range you need from your thermal imager. If your temperature scale is unknown or can be variable, select a camera with a wide temperature range that either automatically selects the range based on your scene or allows you to manually select the temperature range. This feature adds additional cost but ensures your instrument is versatile and functional for many thermal imagery tasks.

4 - Lens Options

Lens options effects the field of view (FOV) and therefore the spatial resolution. There are a diverse range of lens from; standard, wide-angle, telephoto and macro to match your intended application. The standard lens is typically used for the majority of tasks, the wide-lens is commonly used in building inspection tasks and the telephoto lens is commonly used to inspect items at a distance, i.e. pylon insulators.

Standard Wide

5 - Saving IR Images and Additional Data

Capturing and saving data is an important factor to consider when purchasing a thermal camera. The capability to conduct multiple captures and create accessible reports is an important aspect for individuals running preventative maintenance programmes. Organised and easily shareable data enables quick and effective analysis of possible temperature differences over time. Identifying these temperature trends and potential system or mechanical failures is critical to a successful preventative service programme. Most thermal cameras have some capacity to save infrared and digital images to internal memory. Industrial thermal cameras will tend to save images to a removable SD card, or to a USB flash drive. High end industrial thermal cameras may also allow voice notes to be saved. Collating maintenance data over time can help to identify patterns, relationships or issues that otherwise would be difficult to assess and likely remain hidden.

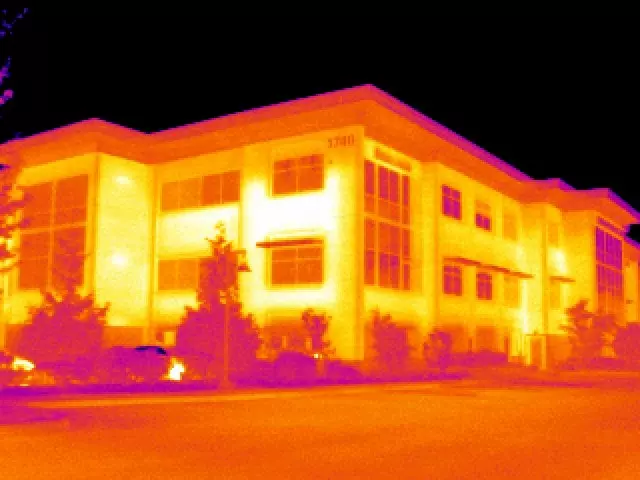

6 - Colour Palette

Colour Palette is linked to the in-built Camera software. High contrast palettes can make it easier to quickly find obvious anomalies. Each user views and interprets thermal images differently, user experience with a particular palette and preference usually dictates which Camera is best suited.

The colour tones correspond to the apparent surface temperatures of the target. The key is to select the palette that best shows the thermal differences for your specific application. Technicians can select or change the palette in the camera user menus and in the software as needed. Higher-end cameras often have a greater choice of colour palettes for the user to implement for specific task requirements.

7 - Colour Alarms

Some infrared cameras offer user-selectable high and/or low apparent temperature colour alarms to quickly highlight areas that are outside of the normal temperature range.

When you scan the area with colour alarms activated you see a visible light image of everything within the high and low parameters. Anything outside of those temperatures appears in infrared. Colour alarms can give you a quick indication of where issues may be so you can focus into specific areas. Colour alarms can speed up testing and efficiency if specific areas are regularly tested under a set maintenance programme. Colour alarms offer inexperienced and experienced technicians a useful aid to ensure the data captured is specific to the target area. Successful industrial maintenance programmes rely on the reliability and accuracy of raw data.

8 - Emissivity and Reflected Temperatures

What is Emissivity? Emissivity (ϵ) is the ratio of how well a material radiates infrared energy, compared to a perfect radiator. Emissivity values fall between 0.0 and 1.0. An object that measures 1.0 is considered a perfect radiator and is called a "black body". Low emissivity surfaces, such as shiny metal can reflect infrared energy from other objects and distort your image and measurement accuracy.

Emissivity varies by surface condition, viewing angle, temperature and spectral wavelength. Most nonmetallic materials are efficient radiators of energy. Human skin is close to a perfect radiator with an emissivity of 0.98. A polished copper surface is at the other end of the spectrum with a value of 0.01. In the real world there are no perfect radiators (1.0) and materials vary in how much less than perfect they are. The effects of emissivity often dictate the method of inspection to ensure accuracy. Experienced thermographers would usually opt for qualitative inspections that focus on apparent temperature difference between comparable equipment under comparable loads, or the same equipment under comparable loads over time. Where as, quantitative inspections rely on obtaining accurate temperature measurements which as we know have the potential to be skewed by the laws of emissivity.

Most high-end thermal cameras have the ability to change the emissivity setting. An experienced thermographer will estimate the emissivity value of the target material under test and adjust the cameras settings to get closer to the actual surface temperature. Emissivity is a complex topic that advanced thermographers understand. The complexity and budget of your intended maintenance programme often dictates the level of infrared testing system that is deployed. Advanced systems would mitigate emissivity, where as basic front-line systems may not require such extensive detail.

9 - Spot Markers

Some cameras allow you to mark specific temperatures on your image to compare simultaneous temperatures from multiple points on the same image. Spot markers allow the thermographer to compare multiple points and assess temperature differences. For example; three equal motors are running under comparable loads and should produce three comparable heat results. In the scenario one motor has a higher operating temperature than the others, quick analysis suggests an issue with one motor that requires further investigation to prevent a future failure.

The functionality of spot markers is typically found on advanced and expensive thermal cameras. Professional users often require spot markers to perform versatile inspections that rely on comparison data. Spot markers act as an inspection aid that is not essential for basic inspection tests.

10 - Battery Type and Life

Battery type and life can vary across brands and models. Battery charge level indicators are a valuable feature that not every unit will have. Long battery life and quick charging ability may be essential to users in specific industries.

Conclusion

Regular infrared inspections can help keep industrial and commercial systems running safely and efficiently. Successful maintenance and preventative servicing relies on reliable data. Accurate or inaccurate data is the difference between a successful or unsuccessful maintenance programme. Ensure your thermal imaging findings are dependable by choosing the correct instrument for the intended task.