Guide on Insulated Gloves for EV/PHEV Diagnostics/Repair

Guide on Insulated Class 0 Gloves for EV/PHEV Diagnostics/Repair

Electrical Insulated Gloves are used to protect a user from electric shock when working on live high voltage electrical systems. There are many different variations of Electrical Insulated Gloves, categorised into one of 5 classes, dependant on the voltage levels that may be encountered and their electrical requirements.

When working on Electric Vehicles (EV) or Plug in Hybrid Electric Vehicle (PHEV) there is a requirement to wear insulating gloves due to the voltages present in their battery packs. Voltages in battery packs on modern vehicles can be anywhere from between 300V and 900V and the correct gloves to wear are those that are categorised as Class 0.

This guide will focus on Class 0 Insulated Gloves that are typically used in EV/PHEV vehicle diagnostics and repair. Discover answers to common queries and questions related to insulated gloves.

1 - What are Insulated Electrical Gloves?

2 - When should insulated gloves be worn?

3 - How to look after your EV Gloves

4 - How to test your insulated Gloves

5 - Insulated Electric Gloves Summary

1 - What are Insulated Gloves?

Electrically Insulated Gloves are also known as electrician gloves or electric gloves. Insulated gloves are designed and manufactured to provide electrical hand protection when working near live voltages. The gloves form a insulative barrier between an electrical point and the skin of an individual, ensuring work can be completed safely and without risk of electrocution.

Electrically Insulated Gloves are categorised by a Class number in accordance with IEC 60903 and EN 60903 standards which determines the insulation rating, performance and suitability for a specific electrical application. The Class ratings are shown below:

Class |

Voltage AC (Max) |

Voltage DC (Max) |

| 00 | 500V | 750V |

| 0 | 1000V | 1500V |

| 1 | 7.5kV | 11.25kV |

| 2 | 17kV | 25.5kV |

| 3 | 26.5kV | 39.75kV |

| 4 | 36kV | 54kV |

2 - When Should Insulated Gloves been worn?

Insulated gloves are commonly used when working with high voltage systems when accidental contact with a live system could be extremely dangerous or even fatal. When working on an EV/PHEV that has its high voltage circuits live, Class 0 electrically insulated gloves must be worn. Warwick Test Supplies specialise in distributing Class 0 insulated gloves for automotive diagnostic technicians. We choose Sibille/Regeltex gloves as being designed and manufactured to offer superior safety and maximum functionality with a priority given to dexterity of the wearer. So they are ideally suited to an automotive technician and the type of work they will be doing.

3 - How to look after your EV insulated gloves?

Improper use or care of electrically insulating gloves can be a matter of life and death. The gloves are generally manufactured from a rubber material and as such are susceptible to damage from sharp objects, dirt and grit. Top Tips on looking after your insulated gloves:

- Always keep your gloves in a storage case when not in use to minimise their exposure to a dirty environment and ultraviolet light. Using a UV resistant case/bag bag is essential. The gloves are easily compromised and damaged from sun light, heat and ozone. The best option to keep your gloves safe is storing them in a hard-case.

- Do not store the gloves folded or rolled up. Store them laid flat in their natural position.

- Do not store any other objects in the glove storage case, unless there is a specific compartment i.e for talc.

- Only wear the gloves when necessary during your work and avoid touching objects, benches, or the floor that may have dirt, dust, grit, grease, solvents or fuel on them.

- Wear leather over gloves over the top of the insulated gloves, especially when in a dirty environment or having to touch or be near sharp objects.

- If the gloves get dirty clean them as soon as possible using clean water and a small amount of mild detergent. Rinse well afterwards and let the gloves dry naturally before placing back in a storage case.

- If the gloves may have been in contact with sharp objects or contaminated by grit or dirt test them before reuse.

- Inspect your gloves before each use and regularly test them to ensure they are fit for purpose and electrically safe.

Look after your electrically insulated gloves, store them in a decent case and they can easily last you 6-8 years.

Do Insulated Gloves have an expiry date?

Electrically Insulating Gloves have no expiry date. Providing the gloves comply with the period of inspection they remain fit for purpose. For Class 0 insulated gloves this means a visual inspection before each use and regular inflation tests. There is no requirement for Class 0 gloves to be regularly electrically tested, although is it recommended.

4 - How to test your Insulated Gloves?

Inspection Before Use

A visual inspection of the gloves should be carried out before each use. Check for tears or nicks and pay close attention to potential pin pricks through the skin of the gloves. If you discover any potential hole in the glove they will not provide adequate protection so must be replaced.

What is the Periodic Inspection Glove Test?

For Class 00 and Class 0 gloves, a visual inspection and check for air leaks is adequate. To check for air leaks a user should perform an inflation and pressure test to ensure the gloves haven’t been pierced or damaged. This involves inflating the glove using air, sealing the end and then checking the whole glove area for air leaks which will indicate the presence of a hole in the glove material.

A dielectric test on the gloves can be performed at the owner’s request and discretion but is not mandatory for Class 0 gloves.

Gloves of Class 1,2,3 and 4, have different rules and even those held in storage should NOT be used unless they have been tested within a maximum period of six months.

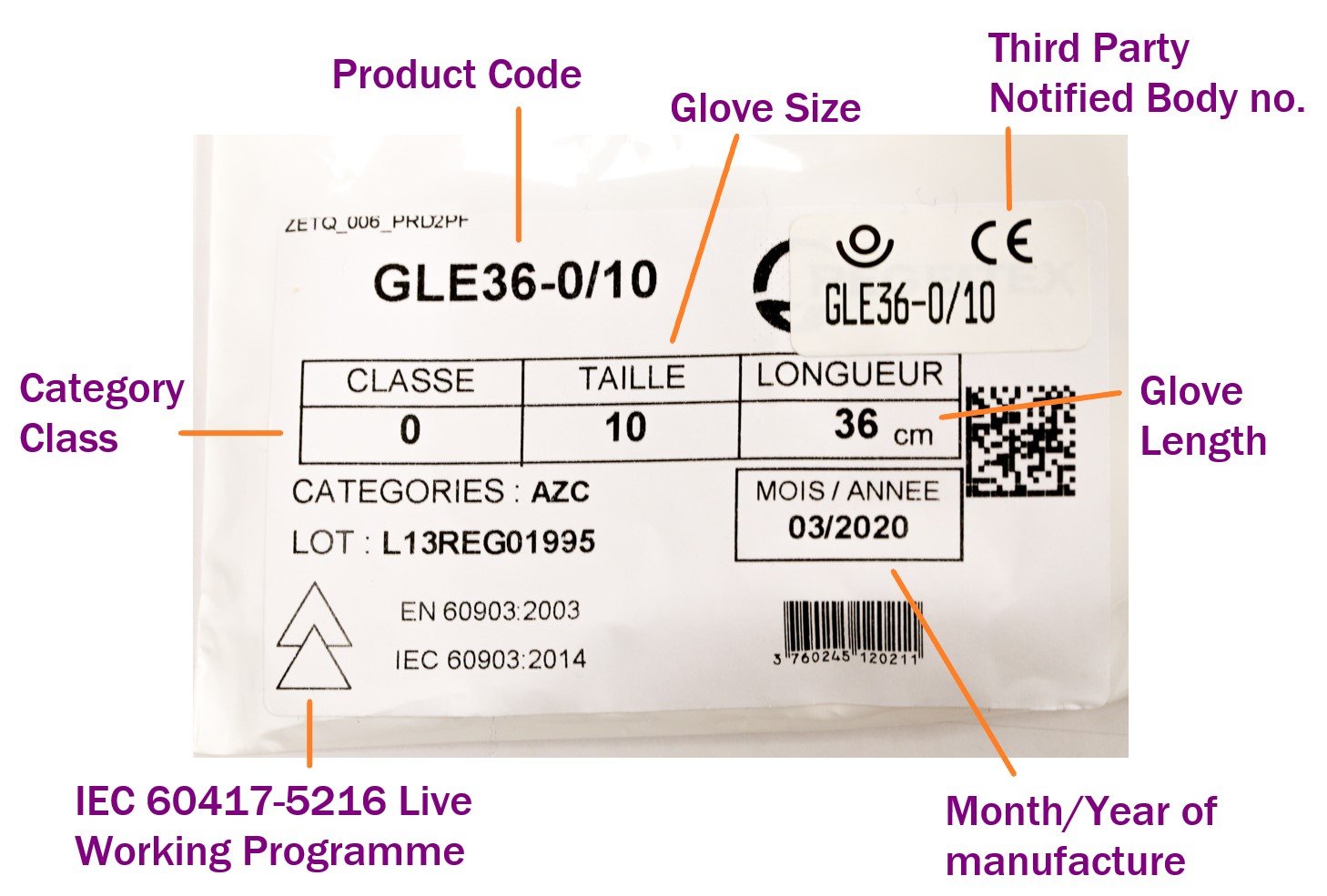

It's important to understand the insulated glove product label information. The Sibille/Regeltex insulated glove label is clear and easy to understand. Many people mis-interpret the date of production with expiry date which as previously mentioned does not exist. As long as Class 0 gloves pass their visual and inflation test they can continue to be used regardless of date of manufacture.

5 - Summary - Electrical Safety Gloves

Choosing the correct Class Rated gloves for your task, correct storage and inspection/ testing before use are 3 critical factors you must follow to ensure safe use of insulated gloves. Electrical testing and measuring will always be associated with risk as energised circuits pose threat of electrical shocks. Many times your insulated gloves are your last line of defence between you and a high-voltage shock. Improper use or care of electrically insulating gloves can be a matter of life and death. Use the Class Ratings table above to assess what level of protection is required and be sure to understand the gloves label and markings before exposing them to any usage. If you have any queries or unclear on what gloves best suit your application contact Warwick Test Supplies for advice and product suggestions.

Sibille Hard Glove Case

Sibille Hard Glove Case  Sibille Hard Glove Case

Sibille Hard Glove Case Sibille Soft Glove Case

Sibille Soft Glove Case